This oxygen-barrier PEX Tubing is sold in 300' and 500' lengths and is designed to be used with the Crete Heat Panels to create an effective radiant floor heat system. Please note the color shipped may not match the picture shown above. It does not include the elbows or fittings as the 300' length kits do (click here). Please call, chat with us below, or email Sales@BarnWorld.com for the shipping total to your address today. This versatile Heat-Flex Tubing is used to transport non-potable water, both hot and cold in applications for radiant floor heating systems including baseboard and snowmelt applications. The Polyethylene Copolymer Resin allows the tubing to carry high-temperature fluids for almost any type of boiler heating system.

HeatFlex PEX tubing is a type of cross-linked polyethylene tubing designed specifically for use in radiant floor heating systems. It offers several advantages: Overall, HeatFlex PEX tubing is a valuable and often required component for radiant floor heating systems, offering flexibility, durability, efficient heat conduction, compatibility, cost-effectiveness, and ease of installation. Oxygen barrier PEX tubing and traditional PEX tubing differ primarily in their ability to prevent the diffusion of oxygen molecules through the tubing material. Here's how they are different: In summary, the key difference lies in the presence of an oxygen barrier layer in oxygen barrier PEX tubing, making it suitable for preventing corrosion in hydronic heating systems that use Electric Floor Heat Boilers, whereas traditional PEX tubing lacks this barrier and is used in other applications.

SELECT LENGTHS HERE

HeatFlex PEX Tubing for Radiant Floor Heating

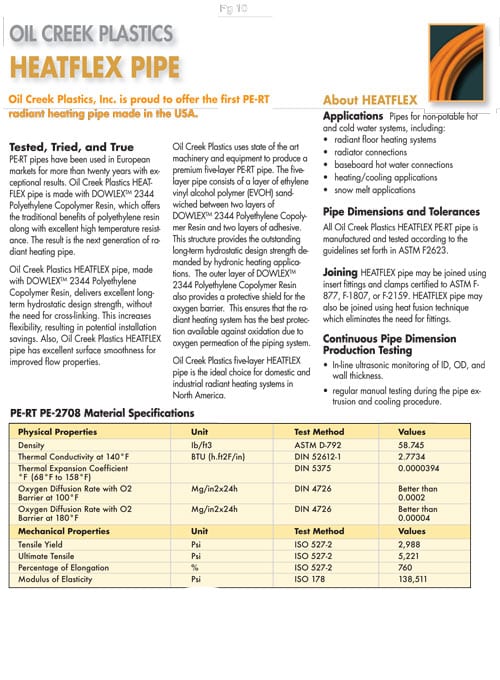

Radiant Floor PEX Tubing Brochure

Link to Brochure

Differences Between Oxygen Barrier PEX and Traditional PEX Tubing

Radiant Heat PEX

This product does not ship free